Ọ bụghị naanị na a na-edozi ezigbo ngwaahịa, kamakwa ọ na-achọ ọgwụgwọ elu dị iche iche iji nweta nguzogide corrosion, iyi nguzogide, ihe ịchọ mma, na ịbawanye ndụ ọrụ.RCT MFG nwere ahụmahụ ọtụtụ afọ na nhazi CNC na nhazi ịkpụzi injection, na-enyekwa usoro ọrụ site na nhazi na ọgwụgwọ elu ruo mgbakọ.Ya mere, na mgbakwunye na teknụzụ mmepụta ihe, ọ nwekwara ahụmahụ bara ụba na ọgwụgwọ elu.Usoro ọgwụgwọ elu dị ugbu a gụnyere: eserese, agba achịcha, mkpuchi ntụ ntụ, ịgba ọkụ, ịgba ọkụ, anodizing, anodizing film siri ike, micro-arc anodizing, electroplating, electrophoresis, laser osise, silk screen printing, brushed metal, mirror polishing, dyeing, blackening, CD ụkpụrụ, etching, elu gloss, etch ụkpụrụ, Epoxy, wdg, nyere aka mee ka ngwaahịa gị dị elu.

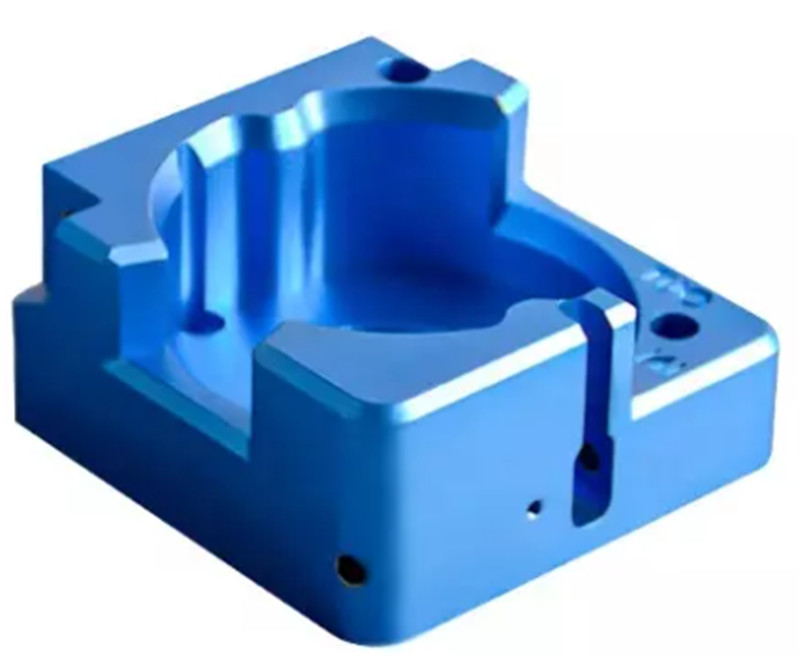

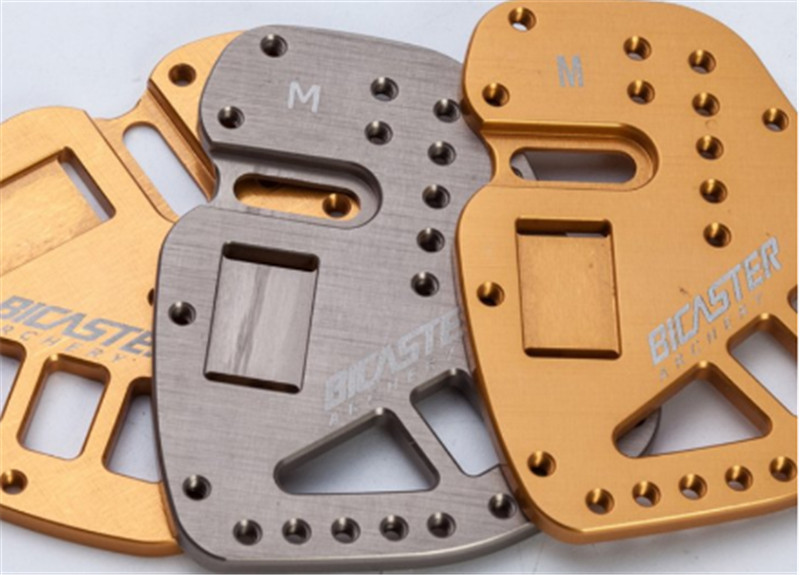

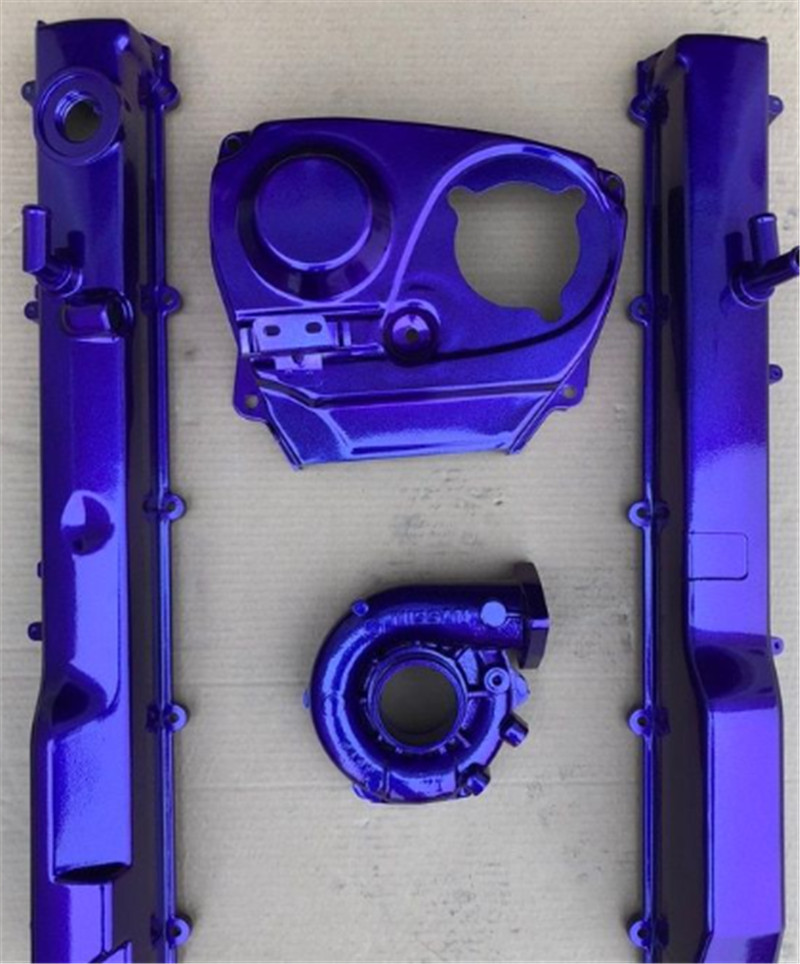

Anodizing

Ọ bụ usoro oxidation electrolytic, nke na-eme ka ihe dị n'elu ihe ahụ ghọọ ihe nkiri nchebe, na-eme ka o sie ike oxidize na corrode, na-eme ka ndụ dịkwuo ogologo ma nweta ọdịdị nke agba dị iche iche.A na-ekewa ọgwụgwọ anodizing ndị a na-ejikarị eme ihe n'ime: anodizing nkịtị, brushed metal anodizing, hard anodizing, oké film anodizing, micro-arc oxidation, wdg. Ihe ndị nwere ike oxidized bụ: aluminum alloy, magnesium alloy, titanium alloy, wdg.

Electrorating

Usoro bụ isi nke electroplating bụ itinye akụkụ ahụ na ngwọta nke nnu ígwè dị ka cathode, na efere ígwè dị ka anode, na-agafe ugbu a iji tinye mkpuchi a chọrọ na akụkụ ahụ.Mmetụta electroplating kwesịrị ekwesị ga-eme ka ngwaahịa gị dịkwuo elu ejiji na ya.N'ahịa ka mma, ọkọlọtọ electroplating gụnyere ọla kọpa plating, nickel plating, silver plating, gold plating, chrome plating, galvanizing, tin plating, vacuum plating, etc.

Ihe mkpuchi electrophoretic

Site na mmụba na-aga n'ihu nke ụlọ ọrụ mmepụta ihe, teknụzụ mkpuchi Electrophoretic nwere ike hazie agba dị iche iche, na-enwe ọmarịcha ọla ma welie nguzogide corrosion nke elu, nke na-enwe obere mmetụta na izi ezi ngwaahịa.Ọkpụrụkpụ ahụ dị ihe dịka 10-25um, yana ndị buru ibu nwekwara ike ịhazi ya

Mmasị

Passivation, nke a makwaara dị ka ọgwụgwọ chromate, bụ usoro nchịkọta nke na-ewepụ griiz elu, nchara, na oxides site na imikpu ma ọ bụ ihicha ultrasonic.Site na mmeghachi omume kemịkalụ nke ngwọta passivation, ọ nwere ike igbochi corrosion na ogologo nchara.Agba nke ihe nkiri passivation ga-agbanwe na ihe dị iche iche.Passivation agaghị eme ka ọkpụkpụ nke ngwaahịa ahụ dịkwuo elu, ọ dịghịkwa mkpa ichegbu onwe ya banyere ya na-emetụta izi ezi nke ngwaahịa ahụ.

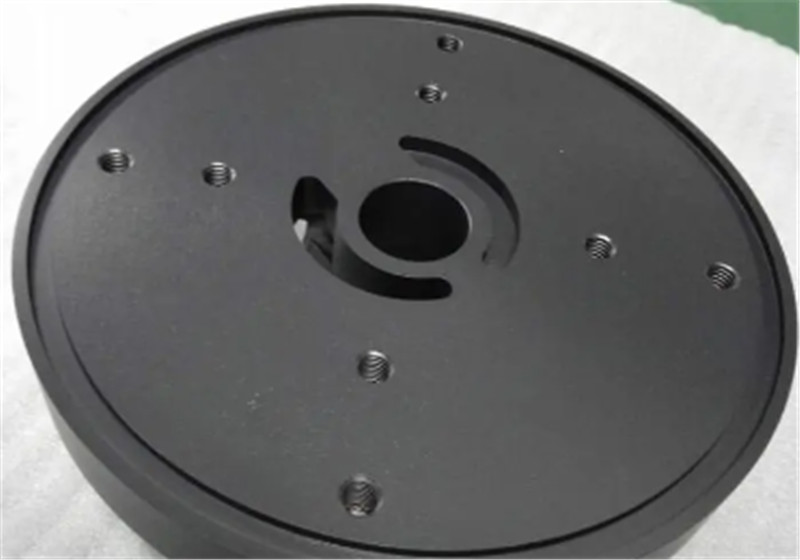

Agbaji oji

A na-akpọkwa oji ojii bluing.Ụkpụrụ bụ imikpu ngwaahịa ahụ n'ime mmiri kemịkalụ siri ike oxidizing iji mepụta ihe nkiri oxide n'elu igwe iji kewapụ ikuku wee mezuo ebumnuche mgbochi nchara.Usoro a na-emetụta ihe nchara.

QPQ (Quench-Polish-Quench)

Ọ na-ezo aka na-etinye ferrous metal akụkụ n'ime ụdị abụọ nke nnu baths nwere dị iche iche Njirimara, na infiltrating dị iche iche ihe n'ime metal elu na-etolite a mejupụtara infiltration oyi akwa, iji nweta nzube nke modifying elu nke akụkụ.Ọ nwere ezigbo mgbochi iyi, ike ọgwụgwụ, nrụrụ corrosion na obere nrụrụ.Usoro a na-emetụta ihe niile ígwè.

(Rịba ama: ngwaahịa igwe anaghị agba nchara enweghị ike ịgbaji oji, naanị QPQ nwere ike mebie elu ya)

Ihe osise laser

Ihe osise laser, nke a na-akpọ akara laser, bụ usoro ọgwụgwọ elu site na iji ụkpụrụ anya iji mepụta LOGO ma ọ bụ ụkpụrụ na ngwaahịa.Mmetụta ihe osise laser na-adịgide adịgide, ogo elu dị elu, ọ dịkwa mma maka ngwaahịa ndị e ji ọla na plastik mee.

Mbipụta ihuenyo silk

Mbipụta ihuenyo silk pụtara na ink na-ebufe ụkpụrụ na ngwaahịa site na ihuenyo.Enwere ike ịhazi agba nke ink dị ka mkpa ndị ahịa si dị.RCT MFG emeela 6 agba na otu ngwaahịa, gụnyere nwa, ọbara ọbara, acha anụnụ anụnụ, odo na ọcha., akwụkwọ ndụ akwụkwọ ndụ.Ọ bụrụ na ịchọrọ ka mmetụta nke mbipụta ihuenyo silk na-adịte aka karị, ị nwekwara ike itinye akwa mkpuchi UV mgbe ebipụta ihuenyo silk ka ọ dị ogologo ndụ ya.Mbipụta ihuenyo silk dabara adaba maka ihe ọla dị iche iche na plastik, enwere ike jikọta ya na ọgwụgwọ elu dị ka oxidation, eserese, spraying powdering, electroplating, na electrophoresis.

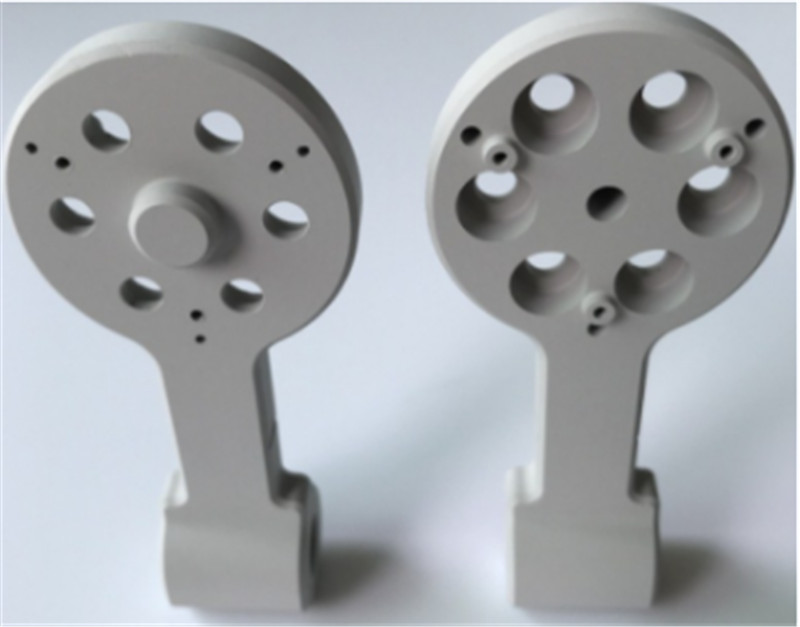

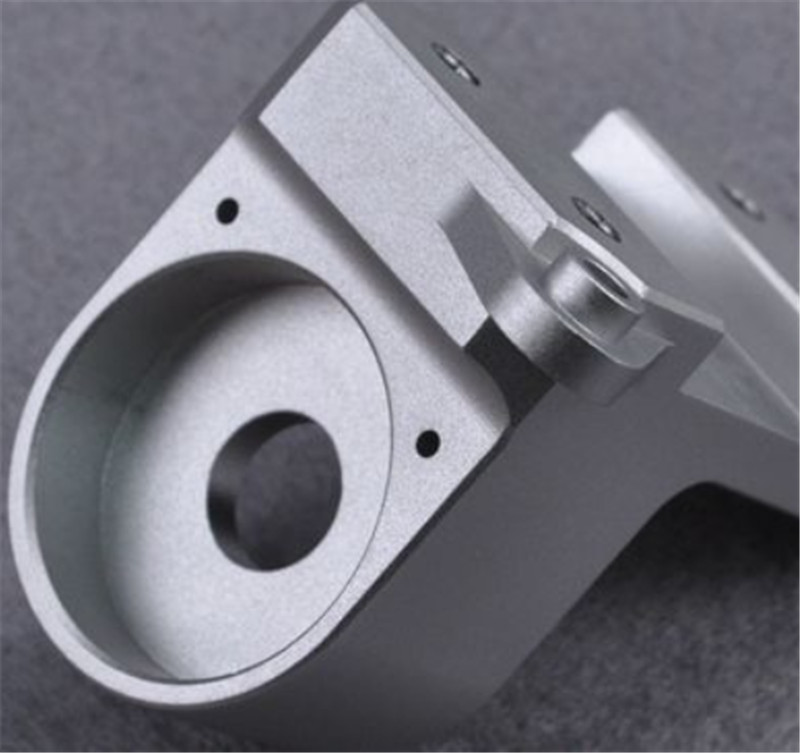

Nchacha

Ntucha bụ ime ka ngwaahịa ahụ mara mma, translucent ma chebe elu.Nchacha na nghọta bụ nhọrọ dị mma maka gị.A na-ekewa nchacha ngwaahịa ngwaike ka ọ bụrụ ncha aka, nchacha igwe, na polishing electrolytic.Enwere ike iji polishing electrolytic dochie akwa polishing dị arọ, karịsịa maka akụkụ ndị nwere ọdịdị dị mgbagwoju anya na akụkụ ndị siri ike ịhazi site na iji aka polishing na usoro n'ibu.A na-ejikarị polishing electrolytic eme ihe maka ígwè, aluminum, ọla kọpa na akụkụ ndị ọzọ.

Igwe a na-akpụ akpụ

Igwe a na-ahịhịa bụ usoro ọgwụgwọ elu nke na-etolite ahịrị n'elu nke workpiece site na eriri abrasive na-arụ ọrụ ewepụghị na ahịhịa na-enweghị akwa iji nweta mmetụta ịchọ mma.Ngwọta elu a na-ahịhịa nwere ike igosipụta ọdịdị nke ihe igwe, ọ na-aghọwanye ewu ewu na ndụ nke oge a.A na-ejikarị ya eme ihe na ekwentị mkpanaaka, kọmpụta, ihe nleba anya, arịa ụlọ, ngwa eletriki na shells ndị ọzọ.

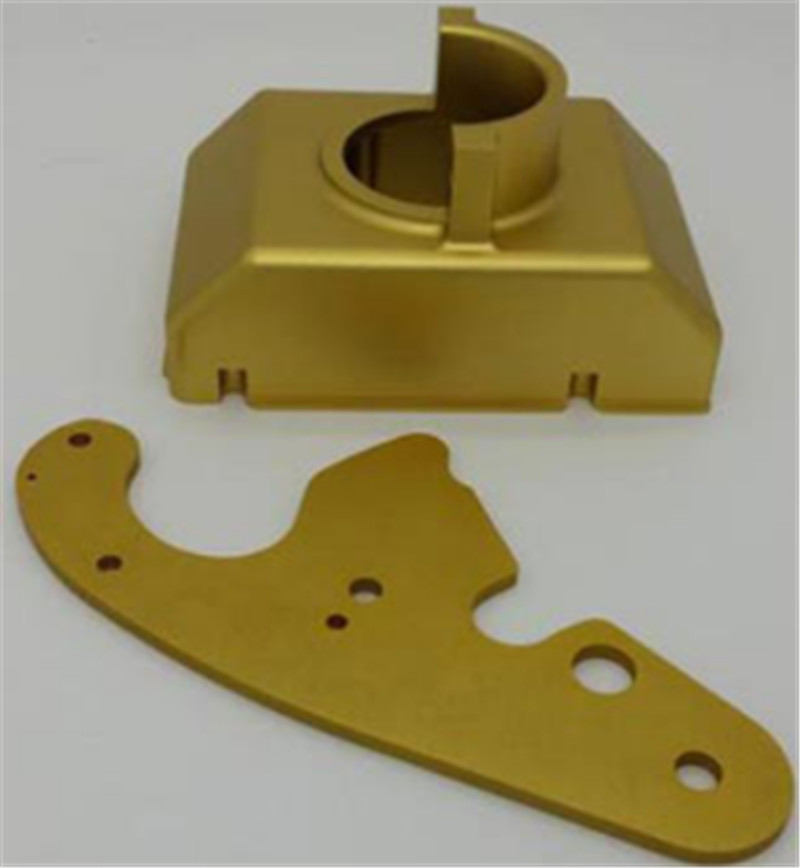

Agba agba na ntụ ntụ

Agba spraying na ntụ ntụ spraying bụ abụọ nkịtị elu agwọ ọrịa na ngwaike akụkụ spraying, na ha bụ ndị a na-ejikarị elu agwọ ọrịa maka nkenke akụkụ na obere ogbe customization.Ha nwere ike ichebe elu site na corrosion, nchara, ma nwee ike nweta mmetụta aesthetic.Ma ntụ ntụ ntụ na eserese nwere ike ịhazi ya na textures dị iche iche (ezigbo ahịrị, ahịrị siri ike, ahịrị akpụkpọ anụ, wdg), agba dị iche iche, na ọkwa dị iche iche gloss (matte, flat, high-gloss).

Mgbawa aja

Sandblasting bụ otu n'ime ọgwụgwọ elu nke a na-ejikarị maka ngwaahịa ngwaike.Ọ nwere ike imeziwanye ịdị ọcha na adịghị ike, ma mee ka adhesion na ogologo oge dị n'etiti ngwaahịa na mkpuchi.Ya mere, ọtụtụ ọgwụgwọ elu na-ahọrọ sandblasting dị ka tupu ọgwụgwọ ha.Dị ka: aja aja + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + uzuzu uzuzu, aja + agba, aja + passivation, wdg.

Teflon spraying

A na-akpọkwa Teflon spraying, ọ bụ ọgwụgwọ elu pụrụ iche.O nwere njiri mara elu nke anti viscosity, enweghị viscosity, oke okpomọkụ na-eguzogide, obere esemokwu, nnukwu ike ike, enweghị mmiri, na nnukwu nguzogide kemịkalụ.Ya mere, a na-ejikarị ya eme ihe na ụlọ ọrụ nri, tableware, kichin, ụlọ ọrụ akwụkwọ, ngwá ọrụ ahụike, ngwaahịa eletrọnịkị na ngwaahịa ụgbọ ala, akụrụngwa kemịkalụ, wdg, ma nwee ike ichebe ihe sitere na corrosion kemịkalụ iji gbasaa ndụ ọrụ nke ngwaahịa.

Etching

Etching bụ usoro nke iwepu ihe site na iji mmeghachi omume kemịkal ma ọ bụ mmetụta anụ ahụ.Na-ezokarị aka na etching, nke a makwaara dị ka photochemical etching, nke na-ezo aka wepụ ihe nkiri nchebe nke ebe a ga-etched mgbe ikpughe efere na-eme na mmepe, na ịkpọtụrụ chemical ngwọta n'oge etching iji nweta mmetụta nke mgbasa na corrosion, na-akpụ mmetụta. concave-convex ma ọ bụ oghere ịkpụzi.

IMD

N'ime ihe ịchọ mma Ebu (IMD) bụ ụzọ dị irè isi chọọ akụkụ plastik mma.Ọ nwere nzọụkwụ anọ: Mbipụta, Akpụpụta, Mbelata na Ịkpụzi Injection.Ọ bụkwa teknụzụ ịchọ mma elu na-ewu ewu n'ụwa niile.Ihe nkiri ahụ siri ike na nke na-apụta ìhè, oyi akwa nke etiti obibi akwụkwọ, oyi akwa ịkpụ injection azụ, na etiti ink nwere ike ime ka ngwaahịa ahụ ghara inwe esemokwu., gbochie n'elu ka a na-akpụ ya, ma nwee ike ime ka agba na-egbuke egbuke ma ghara ịdị mfe ịla n'iyi ruo ogologo oge.

Mpempe akwụkwọ mpempe akwụkwọ

Mpempe akwụkwọ mpempe akwụkwọ, nke a na-akpọkwa tampography ma ọ bụ mbipụta tampo, bụ usoro nbipụta na-apụtaghị ìhè (gravure) ebe ihe mkpuchi silicon na-ese onyinyo 2-D site na mpempe akwụkwọ laser kanyere (etched) (nke a na-akpọ cliché) ma nyefee ya na 3- D ihe.N'ihi mpempe akwụkwọ mpempe akwụkwọ, ọ ga-ekwe omume ugbu a ibipụta ụdị ngwaahịa ndị siri ike dị ka curved (convex), oghere (concave), cylindrical, spherical, compound angle, textures, wdg bụ ndị na-adịghị na usoro obibi akwụkwọ omenala.

Mbipụta nnyefe mmiri

Mbipụta mbufe mmiri bụ ụdị mbipụta nke na-eji nrụgide mmiri mee ka mmiri na-ebufe akwụkwọ / ihe nkiri plastik na ụkpụrụ agba.Usoro nkà na ụzụ na-agụnye ịmepụta akwụkwọ mpempe akwụkwọ na-ebufe mmiri, ịkwanye akwụkwọ ifuru, ịnyefe ụkpụrụ, ihicha, na ngwaahịa emechara.

Ihe mkpuchi na-eduzi

Ihe mkpuchi na-eduzi bụ ụdị agba nke a pụrụ iji mee ihe maka ịgbasa.Ọ nwere ike iduzi ọkụ eletrik mgbe akpọnwụchara ka ọ bụrụ ihe nkiri agba, ka ọ wee chebe nnyonye anya electromagnetic.Ka ọ dị ugbu a, a na-eji ya n'ọtụtụ ọrụ agha na ụlọ ọrụ obodo dịka ngwá electronic, ngwa eletriki, ụgbọ elu, ụlọ ọrụ kemịkalụ, mbipụta, wdg.

Oge nzipu: Eprel 11-2023